How does PMED™ work?

The core PMED technology comprises two distinct elements:

- The formulation of DNA therapeutic vaccines as stable, dry

powders of DNA precipitated onto the surface of microscopic

gold particles and contained within a cassette

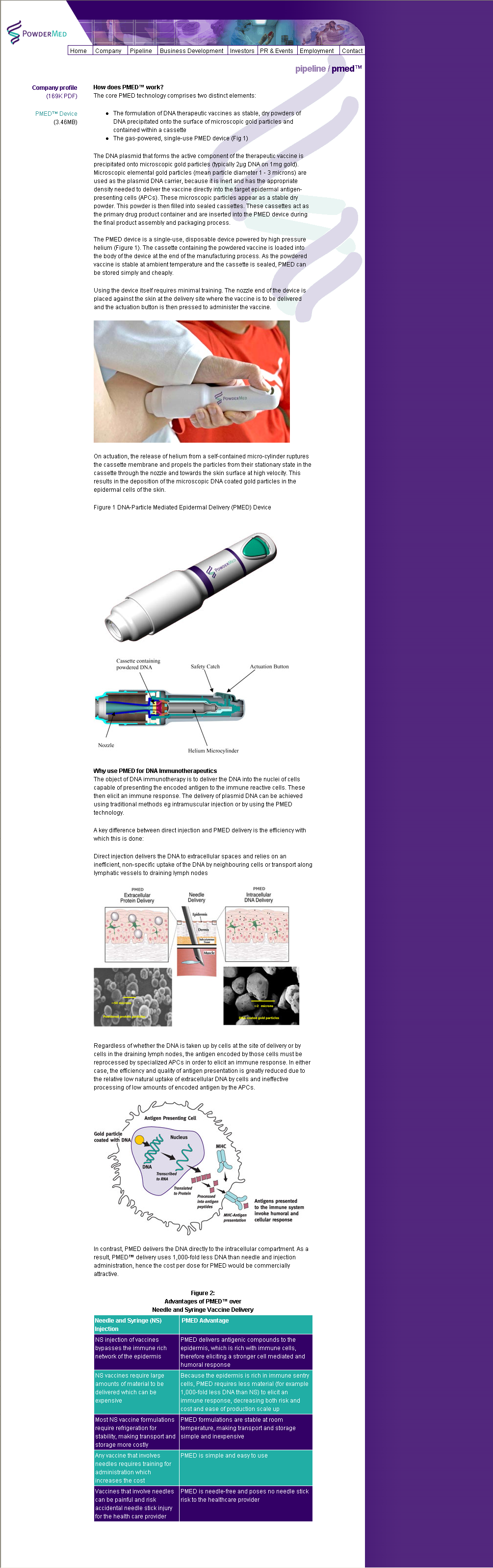

- The gas-powered, single-use PMED device (Fig 1)

The DNA plasmid that forms the active component of the

therapeutic vaccine is precipitated onto microscopic gold

particles (typically 2µg DNA on 1mg gold). Microscopic elemental

gold particles (mean particle diameter 1 - 3 microns) are used

as the plasmid DNA carrier, because it is inert and has the

appropriate density needed to deliver the vaccine directly into

the target epidermal antigen-presenting cells (APCs). These

microscopic particles appear as a stable dry powder. This powder

is then filled into sealed cassettes. These cassettes act as the

primary drug product container and are inserted into the PMED

device during the final product assembly and packaging process.

The PMED device is a single-use, disposable device powered by

high pressure helium (Figure 1). The cassette containing the

powdered vaccine is loaded into the body of the device at the

end of the manufacturing process. As the powdered vaccine is

stable at ambient temperature and the cassette is sealed, PMED

can be stored simply and cheaply.

Using the device itself requires minimal training. The nozzle

end of the device is placed against the skin at the delivery

site where the vaccine is to be delivered and the actuation

button is then pressed to administer the vaccine.

On actuation, the release of helium from a self-contained

micro-cylinder ruptures the cassette membrane and propels the

particles from their stationary state in the cassette through

the nozzle and towards the skin surface at high velocity. This

results in the deposition of the microscopic DNA coated gold

particles in the epidermal cells of the skin.

Figure 1 DNA-Particle Mediated Epidermal Delivery (PMED)

Device

Why use PMED for DNA Immunotherapeutics

The object of DNA immunotherapy is to deliver the DNA into the

nuclei of cells capable of presenting the encoded antigen to the

immune reactive cells. These then elicit an immune response. The

delivery of plasmid DNA can be achieved using traditional

methods eg intramuscular injection or by using the PMED

technology.

A key difference between direct injection and PMED delivery

is the efficiency with which this is done:

Direct injection delivers the DNA to extracellular spaces and

relies on an inefficient, non-specific uptake of the DNA by

neighbouring cells or transport along lymphatic vessels to

draining lymph nodes

Regardless of whether the DNA is taken up by cells at the

site of delivery or by cells in the draining lymph nodes, the

antigen encoded by those cells must be reprocessed by

specialized APCs in order to elicit an immune response. In

either case, the efficiency and quality of antigen presentation

is greatly reduced due to the relative low natural uptake of

extracellular DNA by cells and ineffective processing of low

amounts of encoded antigen by the APCs.

In contrast, PMED delivers the DNA directly to the

intracellular compartment. As a result, PMED™

delivery uses 1,000-fold less DNA than needle and injection

administration, hence the cost per dose for PMED would be

commercially attractive.

|

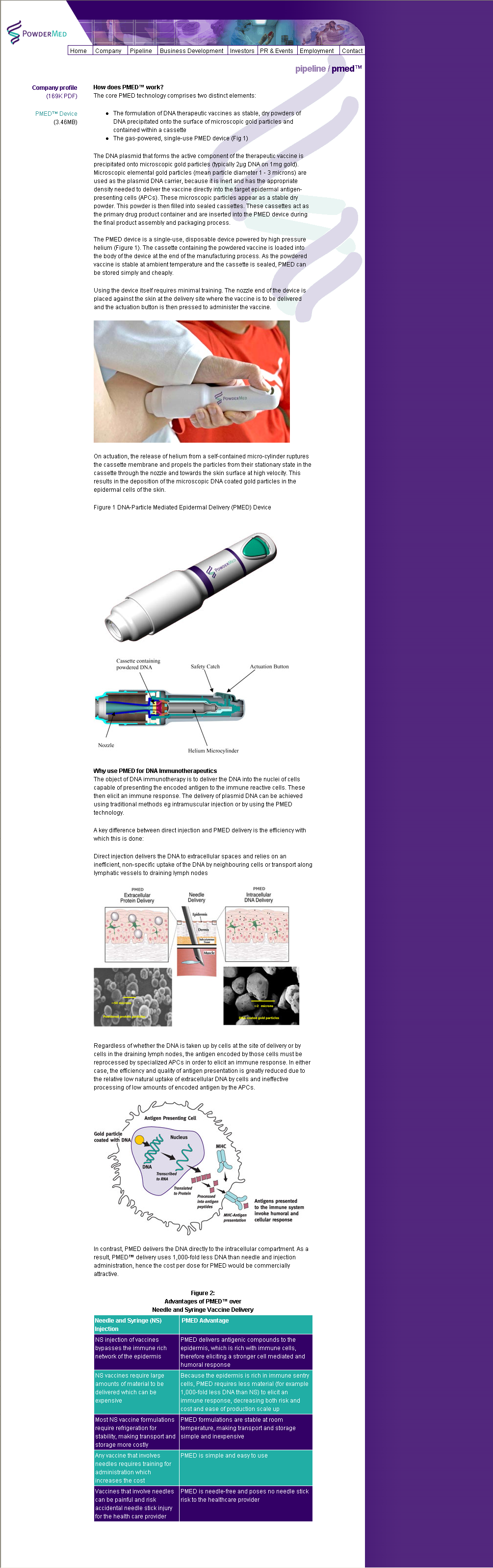

Figure 2:

Advantages of PMED™ over

Needle and Syringe Vaccine Delivery

|

|

Needle and Syringe (NS) Injection |

PMED Advantage |

| NS

injection of vaccines bypasses the immune rich network of

the epidermis |

PMED

delivers antigenic compounds to the epidermis, which is rich

with immune cells, therefore eliciting a stronger cell

mediated and humoral response |

| NS

vaccines require large amounts of material to be delivered

which can be expensive |

Because the epidermis is rich in immune sentry cells, PMED

requires less material (for example 1,000-fold less DNA than

NS) to elicit an immune response, decreasing both risk and

cost and ease of production scale up |

| Most

NS vaccine formulations require refrigeration for stability,

making transport and storage more costly |

PMED

formulations are stable at room temperature, making

transport and storage simple and inexpensive |

| Any

vaccine that involves needles requires training for

administration which increases the cost |

PMED

is simple and easy to use |

|

Vaccines that involve needles can be painful and risk

accidental needle stick injury for the health care provider |

PMED

is needle-free and poses no needle stick risk to the

healthcare provider |

|